FTO Turbo Project - PICS **UPDATED

Moderators: IMC, Club Staff

- bigpitty1

- Mechanic

- Posts: 629

- jedwabna poszewka promocja

- Joined: Thu Mar 18, 2004 6:00 pm

- Location: Mackay

-

RedlineGX

- Grease Monkey

- Posts: 289

- Joined: Sat Aug 21, 2004 5:00 pm

- Location: Barbados

- Contact:

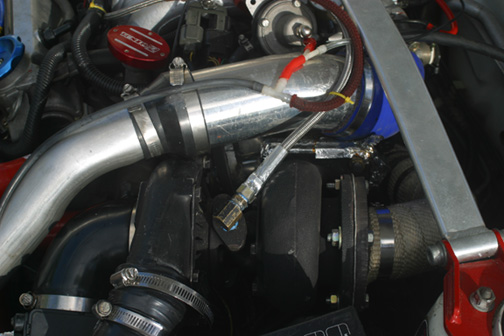

Ok got everything more or less finished up yesterday. Just a few things left like tidying up the wires and vaccuum hoses etc. and the uppipe needs a gasket since its leaking air and causing the turbo to spool a little later than it should. However i turned up the fuel pressure and took it for a little drive and everything is working great but cant really push it till i get it tuned after Christmas.

Here are some more pics...

Oil Return Tap on Oil Pan

Oil Return Line

Oil Feed Line

FMIC

Down Pipe to Muffler

Engine Bay

Turbo

Interior

Here are some more pics...

Oil Return Tap on Oil Pan

Oil Return Line

Oil Feed Line

FMIC

Down Pipe to Muffler

Engine Bay

Turbo

Interior

- Supplanter

- Forum Moderator

- Posts: 6420

- Joined: Tue Oct 22, 2002 5:00 pm

- Location: Arizona Bay

- Contact:

-

RedlineGX

- Grease Monkey

- Posts: 289

- Joined: Sat Aug 21, 2004 5:00 pm

- Location: Barbados

- Contact:

-

NorthQLDFTO

- Grease Monkey

- Posts: 252

- Joined: Sat Jan 29, 2005 6:00 pm

- Location: Townsville, North Queensland

I can see the pics fine! Looks awesome buddy! Keep us posted on your progress...

I am SO doing this now!!!

I am SO doing this now!!!

If I Had A Dollar For Every Time Someone Said "If I Had A Dollar For Every Time Someone Said <...>" Well... Then... I'd... Have A Dollar For Every Time Somone Said "If I Had A Dollar For Every Time Someone Said <...>"!!!

-

mr_bishi

- Grease Monkey

- Posts: 237

- Joined: Wed Jan 05, 2005 6:00 pm

- Location: Rugby,England

That looks bloody great mate......a nice neat installation

By the looks of it you've used the rpw's too.....good work!

What boost gauge have you used? I can't seem to find one that reads less than 20 psi

By the looks of it you've used the rpw's too.....good work!

What boost gauge have you used? I can't seem to find one that reads less than 20 psi

[url=http://www.sloganizer.net/en/][img]http://www.sloganizer.net/en/style8,mr-dot-bishi.png[/img][/url]

-

RedlineGX

- Grease Monkey

- Posts: 289

- Joined: Sat Aug 21, 2004 5:00 pm

- Location: Barbados

- Contact:

Thanks guys, from the time I got all the parts to the time it was rolling was exactly 6 days working about 6 hours a day. Mostly just me with an occasional hand fitting stuff but you will need a ramp to get that done. 80% off that time was spent fabricating the pipes. I would reccommend getting the rpw pipes since it makes the uppipe a lot easier and also improves flow to the turbo. I also got the thermal gasket for the intake manifold and bored out 65mm TB at the same time.

It's really not that hard people. Before I started this I wasnt even very familiar with the workings of turbos etc altho I would consider myself mechanically minded, but I still got through quite easily and it really hasnt cost that much.

You wont find many boost gauges with less that 20psi most read to 30. I'm using an autometer phantom series one to match back with the white dials.

Going to get it tuned soon, should be great. I pushed it once to see if the wastegate was working and even though it was running lean it felt great, but cant afford to do that again.

Got to take back off the turbo though cause the gasket for the uppipe is leaking a bit so need to get another one or fabrcate one cause that will def hurt performance a bit.

It's really not that hard people. Before I started this I wasnt even very familiar with the workings of turbos etc altho I would consider myself mechanically minded, but I still got through quite easily and it really hasnt cost that much.

You wont find many boost gauges with less that 20psi most read to 30. I'm using an autometer phantom series one to match back with the white dials.

Going to get it tuned soon, should be great. I pushed it once to see if the wastegate was working and even though it was running lean it felt great, but cant afford to do that again.

Got to take back off the turbo though cause the gasket for the uppipe is leaking a bit so need to get another one or fabrcate one cause that will def hurt performance a bit.

-

RedlineGX

- Grease Monkey

- Posts: 289

- Joined: Sat Aug 21, 2004 5:00 pm

- Location: Barbados

- Contact:

- SchumieFan

- Oldtimer

- Posts: 5875

- Joined: Thu Aug 05, 2004 5:00 pm

- Location: GPS signal lost

- Contact:

- dannyboyau

- Veteran Mechanic

- Posts: 979

- Joined: Sat Sep 28, 2002 5:00 pm

- Location: that speck disappearing in the distance

-

RedlineGX

- Grease Monkey

- Posts: 289

- Joined: Sat Aug 21, 2004 5:00 pm

- Location: Barbados

- Contact:

Thanks...

Running a Greddy Emanage right now.

Got it tuned the other day and its working great, no problems so far.

Car feels great when boost kicks in. I would love to get some forged internals and up it to about 12 psi...

If not for the price of forgies...

We dont have a strip down here so I'll have to g-tech it ad see what it does.

Running a Greddy Emanage right now.

Got it tuned the other day and its working great, no problems so far.

Car feels great when boost kicks in. I would love to get some forged internals and up it to about 12 psi...

If not for the price of forgies...

We dont have a strip down here so I'll have to g-tech it ad see what it does.

-

RedlineGX

- Grease Monkey

- Posts: 289

- Joined: Sat Aug 21, 2004 5:00 pm

- Location: Barbados

- Contact:

Maybe he meant 2.9? That would feel pretty good.

Was wondering if anyone knew how much pressure the crankshaft could take safely? I know you can get forged pistons and connecting rods but surely the crank would need improving as well to make it worth it.

I've heard stories of people daily pushing 10 pounds of boost safely through with stock internals and no issues once the tuning was done properly and adequate cooling, i.e. water injection, good size I/C with boost sensitive direct water nozzle spray onto it(which i am getting soon since the greddy can control ), and oil cooler.

), and oil cooler.

Anyone else heard of this?

Was wondering if anyone knew how much pressure the crankshaft could take safely? I know you can get forged pistons and connecting rods but surely the crank would need improving as well to make it worth it.

I've heard stories of people daily pushing 10 pounds of boost safely through with stock internals and no issues once the tuning was done properly and adequate cooling, i.e. water injection, good size I/C with boost sensitive direct water nozzle spray onto it(which i am getting soon since the greddy can control

Anyone else heard of this?

- dannyboyau

- Veteran Mechanic

- Posts: 979

- Joined: Sat Sep 28, 2002 5:00 pm

- Location: that speck disappearing in the distance

- SchumieFan

- Oldtimer

- Posts: 5875

- Joined: Thu Aug 05, 2004 5:00 pm

- Location: GPS signal lost

- Contact: